- Products

- Catalogs

- News & Trends

- Exhibitions

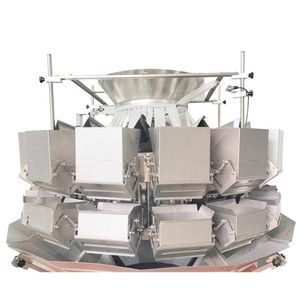

Walnut batch weigher OYDE-ZH14-2.5 fruitfor meatwith bagger

Add to favorites

Compare this product

Characteristics

- Application

- fruit, for meat, walnut

- Other characteristics

- with bagger, with conveyor

Description

The material is conveyed from a material conveyor to the multi-head scale's material hopper. lnside the multi-head scale's material hopper, the vibration from the main vibrator ensures the uniform discharge of material from the main vibrating plate. This material then enters the linear vibrating plate and isdistrilbuted to various linear vibrating plates. The vibration of the linear vibrators causes the material to be discharged from each line's vibrating tray and enter the feeding hopper for storage.

When a weighing bucket of the multi-head scale completes one weighing cycle and empties, the loading hopper is opened to allow material to enter the weighing bucket for weighing. Output sianals are transmitted through wires to the control equipment's main board. The CPU on the main board readsand records the weight of each weighing bucket, and select the combination of weighing buckets that is closest to the target weight through calculations, analysis, and combination.

When there is an allowed discharge signal, the CPU issues a command to start the drive, opening the selected weighing bucket of the multi-head scale. The material is then conveyed through a chute to the collecting hopper or directly sent to the multi-head scale packaging machine. An unloading signal is sent to the multi-head scale packaging machine to complete the packaging process.

Applications

Fruit snacks: dried pomelo, durian, mango, pistachios, melon seeds, etc.

Aquatic products: sea cucumber, dried abalone, etc.

Poultry segmentation products: chicken feet, middle wings, drumette, second-joint wings, etc

VIDEO

Related Searches

- Top-tailer

- Vegetable crop cleaning machine

- Automatic sorting table

- Bucket elevator

- Potato haulm separator

- Automatic grader

- Vertical bucket elevator

- Carrot crop cleaning machine

- Automatic crop cleaning machine

- Batch weigher

- Grader with cleaning system

- Fruit crop cleaning machine

- Batch weigher with bagger

- Vegetable batch weigher

- Z bucket elevator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.