- Farm Management

- Measuring instrument

- Qingdao Ouyade

- Products

- Catalogs

- News & Trends

- Exhibitions

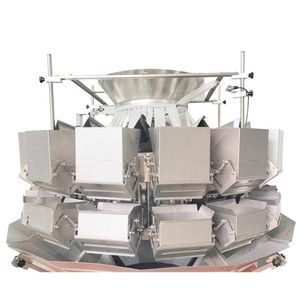

Fish weighing machine OYDE-FZHC-037vegetable

Add to favorites

Compare this product

Characteristics

- Applications

- vegetable, for fish

Description

The double-layer flap combination scale controls the rotation of the bearing through the program, and the first-layer weighing platform flips over. Each weighing platform is equipped with a sensor corresponding to two counterweight platforms.

When the material is placed on the weighing plattorm, the weighing sensor weighs in real time and transmits the data to the data processing system. The main control board controls the weighing platform to flip to the left or right to the corresponding position, and the material in the weighing platform will fall into the second-layer counterweight platform.When the weight of the material in N counterweight platforms meets the set counterweight target, Nmaterials fall into the same conveyor belt grid, that is, the counterweight is successful, and the material is transported backward.

Parameters

Single Platform Size - L215mmxW146mm(Customized)

Number of scales - 12 Weighing Stations +24 Counterweight Stations(Customized)

Weighing sensor - HBM

Tolerance Range - ±2g

Production Capacity - 20-50times/min

Voltage - 220V/AC 7 KW(Customized)

Equipment Size - L11800mmW1200mmH1560mm(Customized)

Equipment Material - SUS304 Stainless Steel

Waterproof Grade - IP65

Applications

Fruits and vegetables: frozen durian, jackfruit, etc.

Aquatic products: crabs, fish, etc

Others: meat,snacks, etc

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.