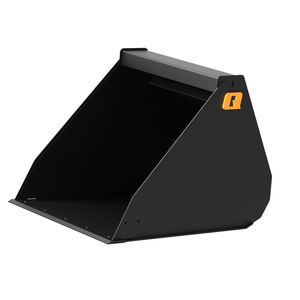

Silage unloading shovel bucket SILOCUT® SG SERIES

Add to favorites

Compare this product

Characteristics

- Type

- silage unloading

Description

The new Silocut features welded tine sleeves, bolt on knifes, conus 3 tines and upgrades that improves serviceability.

Thanks to the hardened cutting knifes on the front edge and sides of the Silocut, it leaves a clean cut surface in the silage. Angled side knifes cut against the side plates to ensure the material is cut towards the rear of the Silocut, preventing tearing and create a clean side cut. By having a clean cut, it prevents the admission of air and generation of heat, critical for feed quality, while consuming less silage by reducing waste. Manageable cut blocks can be transported in compressed form, reducing handling time.

Silocut 175 SG, is a new model at 1.75 m width with 2 cylinders at 524 kg, light enough for users wanting more volume in the 60-100 hp range of machinery. This fits in a new width range of 1.25 m – 2.25 m, with 25 cm increments between each model. Larger 3 cylinder models at 2 m and 2.25 m have hooks are available for BM / JCB wheel loaders as well as Front Loaders.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Quicke‘s catalogsRelated Searches

- 2-tine fork

- Loader shovel bucket

- Bale handler

- Front loader

- Round bale handler

- Bale spear

- Pallet fork

- Silage unloading shovel bucket

- Digging shovel bucket

- Loader fork

- Compact tractor front loader

- Fork with hydraulic adjustment

- Front linkage

- Front loader with parallelogram limkage

- Manure fork

- Silage fork

- Square bale handler

- Screening shovel bucket

- Bag lifter

- Skeleton shovel bucket

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.