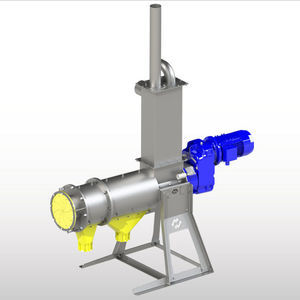

Screw slurry separator Pulp and Paper Horizontal

Add to favorites

Compare this product

Characteristics

- Other characteristics

- screw

Description

SEPCOM Pulp and Paper Horizontal is an innovative screw press solids-liquid. Thanks to its special features like the compensator hopper tank, the self-adjusting counter-pressure diaphragm and special screw types, a variety of materials from biogas plants, industrial processes, as well as slurry from livestock breeding can be treated.

Description

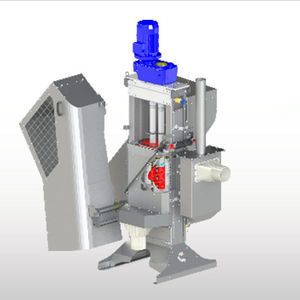

The SEPCOM Pulp and Paper Horizontal Screw Press Separator consists of a feeding section provided with a compensator tank and overflow hopper. The stainless steel casing includes a screw conveyor and a cylindrical screen basket that conveys and separates the solids from the liquid phase flowing through the screen, while the solid fraction is pushed towards the counter-pressure diaphragm outlet where a material plug forms. This enables automatic operation of the separator preventing the liquid phase from flushing through.

The drive unit consists of an electric motor and a gear reducer equipped with a splined output shaft which is directly coupled to the conveyor screw.

SEPCOM Pulp and Paper Horizontal is particularly specialized for pulp and paper treatment.

Function

SEPCOM Pulp and Paper Horizontal is a solids-liquid separating machine based on screw conveyor technology. Performing separation by both gravity and mechanical compression, the machine is designed to separate the liquid phase from the solid phase of a wide range of materials such as sludge, sewage, manure, vegetable and fruit processing waste and, in general, solids-liquid mixtures in which the percentage of liquid inside the solids may differ considerably. The separated solid phase and liquid phase can both be easily and cheaply handled.

Catalogs

No catalogs are available for this product.

See all of SAVECO‘s catalogsRelated Searches

- Electric pump

- Manure pump

- Submersible pump

- SAVECO slurry separator

- Treatment system

- Vertical pump

- Horizontal slurry mixer

- Water treatment system

- SAVECO screw slurry separator

- SAVECO screen

- Pump with cutter

- Wastewater treatment system

- Submersible slurry mixer

- Drum screen

- SAVECO mechanical screen

- Bedding slurry separator

- Fine screen

- Slurry separator with pump

- Belt screen

- Waste treatment system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.