- Farm Machinery

- Harvesting

- Grain pre-cleaner

- Schneider Jaquet

- Products

- Catalogs

- News & Trends

- Exhibitions

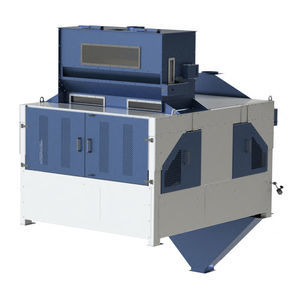

Grain pre-cleaner SNST 2150seedvibrating meshseparator

Add to favorites

Compare this product

Characteristics

- Application

- for grain, seed

- Type

- vibrating mesh

- Other characteristics

- separator

Description

APPLICATION

The SNST 2150 separator-cleaner is designed for multiple uses and meets all cleaning needs: from basic cleaning upon reception and before storing to very fine cleaning before shipment.

The basic cleaning flow rate is 200 tph for wheat, but it can be adapted to any type of grain or seed: wheat, corn (maize), barley, oat, flax, rapeseed, peas, broad beans, etc.

OPERATION

Schneider Jaquet separators-cleaners operate on the basis of planetary movement, allowing better distribution of grains all over the sifting surface and thus enhancing the flow rate and yield.

This machine combines the functions of a dust remover, screener, lump breaker and scrubber, making the best of the most reliable techniques currently available for this work. It is made of a hanging casing that is set in planetary motion by out-centred masses driven by a vertical shaft and low-power electrical motor.

1- Grain is fed into a feeding casing which spreads it in an even layer over the entire width of the machine.

2- Once the good product is obtained, it is fed through eight lump-breaking sifts that remove large waste or bigger grains and direct them to the large waste exit. The good product is then fed through eight screening sifts that separate fine products and direct them towards the screenings exit.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.