- Farm Infrastructure

- Waste management

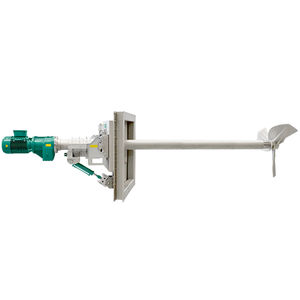

- Vertical agitator

- SUMA Rührtechnik

Horizontal agitator GIANTMIX FR SPverticalelectrically-poweredstainless steel

Add to favorites

Compare this product

Characteristics

- Orientation

- horizontal, vertical

- Other characteristic

- electrically-powered, stainless steel, hydraulic, side-mounted

Description

•Suitable up to 8 m beneath substrate level. Deeper immersion depths on request

•Horizontally adjustable +/- 25°

•Vertically adjustable up to 30° through hydraulic cylinder or pinion

•Authorized for ex-zone 1 within the tank

•A 13,5 kW version is available for ex-zone 1 outside the tank

•Sealing plates 98 x 98 / 120 x 120 / 143 x 143 cm V2A (ss304) or V4A (ss316)

•Tube and sealing plate in ss304 or ss316

•Tube Ø 101,6, ss304 or ss316

••Propeller in hardened steel, ss304 or ss316

POM protection to minimize abrasion

Application:

The Giantmix FR SP has been specially designed to optimize the biological processes in fermenter and end storages with nearly constant substrate levels.

Installation depth:

Because of the unique SUMA-sealing system, the installation depth of 8 m beneath substrate level but full swivel range is possible. Deeper immersion depths on request.

Sealing system:

The flexible tube leadthrough gets sealed with 2 EPDM sealing membranes (inside and outside) and a special sealing system of SUMA.

Easy maintenance:

One advantage of the design of the Giantmix is that almost all of maintenance duties can be carried out from the outside, which means that opening the fermenter or dismounting the unit is not necessary.The drive side with the electric motor and transmission is accessible from the outside; only the shaft tube and propeller are within the fermenter and in an optimal position for proper mixing.

Optional PTO drive:

The Giantmix FR can be ordered with an optional protective device and PTO connection.

Catalogs

GIANTMIX FR SP

2 Pages

2023 Agitators & Pump for biogas

36 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.