- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

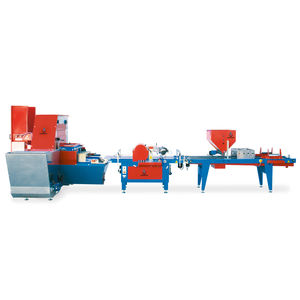

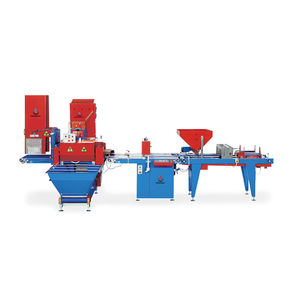

Drum seeding line SIGMA80automaticnaked seedcoated seed

Add to favorites

Compare this product

Characteristics

- Type

- automatic

- Seed type

- pelleted seed, naked seed, coated seed

- Other characteristics

- row, drum

- Trays/hour

1,800 unit

Description

The SIGMA80 drum seeding line is a high-performance line thanks to the use of an 800 mm conveyor belt that allows the containers to be used in a transverse position rather than longitudinal to the direction of travel.

It is equipped with an infeed conveyor belt for the stacks of empty containers which guarantees a constant flow to the distributor located before the tray filler.

It is suitable for all types of trays: polystyrene, thermoformed and injection. The tray filler guarantees excellent uniformity of all the cells and the ability to adjust the final density of the soil.

The trays exiting to the tray filler are processed by the motorised dibbler drum: the perfect synchronisation between the advancement of the container and the dibbler drum guarantees a centred position of the hole with respect to the cell and a perfectly regular shape.

The sowing drum then allows individual distribution of the seeds in the cells, whether they are small or large.

Lastly, the covering and watering unit complete the seeding cycle and the stacking unit, with the balance stacker, sorts the newly seeded containers in orderly stacks to make it easier to extract or palletise them.

Each component of the machine is designed and built according to the customer’s needs, to improve the work of the operators, to reduce maintenance and speed up seed change operations.

This product is Made in Italy.

For more information visit www.urbinati.com

Catalogs

No catalogs are available for this product.

See all of URBINATI Srl‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Belt elevator

- Mobile elevator

- Potting machine

- Tray filler

- Automatic potting machine

- Soil mixer

- Height-adjustable elevator

- Container conveyor

- Automatic tray filler

- Automatic soil mixer

- Transplanting machine

- Stationary soil mixer

- Automatic transplanting machine

- Seeding line

- Automatic seeding line

- Transport system

- Horticulture production line

- Automatic horticulture production line

- Destacker

- Pot conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.