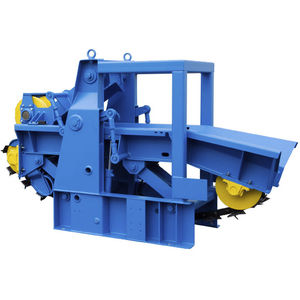

Feed conveyor VK52for firewoodrollerwith hydraulic adjustment

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- feed, for firewood

- Technology

- roller

- Other characteristic

- with hydraulic adjustment

Description

The centring infeed conveyor ensures a good grip of the log at the start of the debarking phase and an accurate control of log onto the debarker’s infeed line. VK infeed conveyors centre the logs both vertically and horizontally (X–Y centring) using a conveyor trough and a flap/roll, which places pressure on the log. The feeding of logs into the debarker is aided by the shape of the infeed conveyor’s flight chain – the flights push the logs forward.

The new infeed conveyor model VK52 was introduced onto the market in the mid-2000s. Several dozen of these machines have already been delivered throughout the world. The model was specifically designed for small and medium-sized logs. The conveyor includes all the critical components along with structures that are sturdier than before. The conveyor is protected on both sides by guard doors and the necessary protective fences that observe all occupational safety requirements. All of the VK52 conveyor’s lubrication points are connected to the debarker’s central lubrication system. The conveyor is available as standard equipment in the following machine models: VK5048HD, VK5062HD, VK5044HD, VK5056HD and VK5000HD Combi models.

VIDEO

Catalogs

No catalogs are available for this product.

See all of valonkone‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.