- Farm Infrastructure

- Storage & Conveying

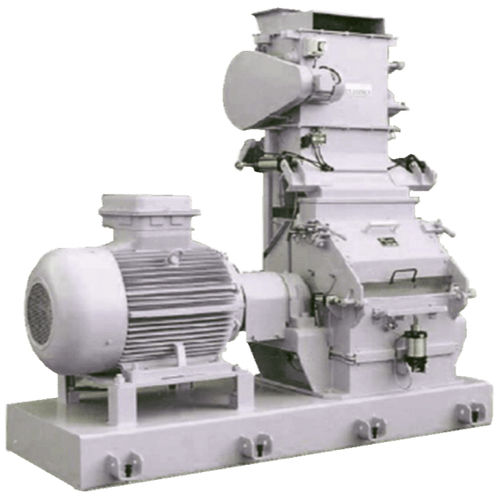

- Grain mill

- Van Aarsen International B.V.

Grain mill 2D seriesfor animal feedhammerstationary

Add to favorites

Compare this product

Characteristics

- Application

- grain, for animal feed

- Type

- hammer

- Other characteristics

- stationary

- Production capacity

Max.: 25 t/h

(15.31 lb/s)Min.: 5 t/h

(3.06 lb/s)

Description

The GD and 2D hammer mills are designed for the animal feed industry, to grind raw materials into small particles and meal. Both the GD and 2D hammer mill series cover capacities ranging from 5 – 100 tons per hour, dependent on type of raw material, formula and required grinding structure and can be incorporated in a pre-grinding as well as a post grinding system as a complete grinding solution including pre-bin, feeder, magnet cleaner, hammer mill, discharge hopper, aspiration filter, fan and control system.

Split Grinding, Post Grinding and Pre Grinding

Grinding raw materials to the required structure is an essential operation in a feed mill.

Split Grinding

Split Grinding is a new Van Aarsen solution that helps optimize the nutritional value of the feed by splitting up one batch of raw materials into two sub-batches which are separately dosed and grinded.

Split Grinding combines the best of both worlds:

•Interesting for feed mills with both a few and many recipes

•Requires a Hammer mill fitted with an automatic screen exchange

Compared to a Post Grinding batch process this leads to

•Optimization of the nutritional value of the feed

•Less energy consumption during the grinding process

•Higher line-capacity by an increased number of batches per hour

VIDEO

Catalogs

No catalogs are available for this product.

See all of Van Aarsen International B.V.‘s catalogsOther Van Aarsen International B.V. products

Hammer mills

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.