- Livestock Farming

- Livestock equipment

- Vertical mixing wagon

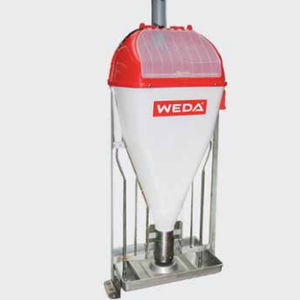

- WEDA Dammann & Westerkamp GmbH

Vertical feed mixer TM60/TM120stationarywith weighing system

Add to favorites

Compare this product

Characteristics

- Auger orientation

- vertical

- Mobility

- stationary

- Other characteristic

- with weighing system

- Capacity in m³

Max.: 120 l

(31.7 gal)Min.: 60 l

(15.9 gal)

Description

With the TM60/TM120 weighing mixer, a wide variety of dry feed types can be combined and mixed according to individual needs and then dosed out into independent feed circuits via computer control and distributed with pinpoint accuracy. For mixing, the components are placed in the 60 or 120 litre mixing tank and mixed thoroughly and at the same time gently by the conically shaped spiral agitator. For the best possible quantity control of the components, the mixer is monitored by two load cells with a 10-gram resolution.

To allow for a parallel mixing and dosing out, the feed is transferred through a flap gate into the storage tank below after the mixing process. That way, the mixer can prepare the next batch without any loss of time, while the feed is being dosed out of the storage tank into the individual feed lines. With the help of the flap gate, the optionally divided chambers of the storage tank can be filled separately and, in this way, up to four feed lines can be connected.

Another advantage of the new batch mixer is its low overall height. This means that it can be installed in rooms with normal ceiling heights. For the necessary hygiene and durability, the weighing mixer is made entirely of stainless steel.

Catalogs

No catalogs are available for this product.

See all of WEDA Dammann & Westerkamp GmbH‘s catalogsOther WEDA Dammann & Westerkamp GmbH products

Dry Feeding

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.