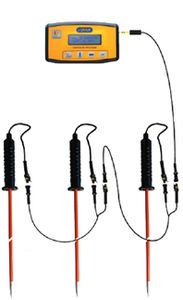

Grain storage grain probe

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Options

- for grain storage

Description

The iGRAIN Sensor Probes are designed to monitor the biological processes during storage in silos and containers. The monitoring is based primarily on gas analysis.

Because ambient air surrounding the grain kernels spread evenly and rapidly in a silo or container, a single point measurement is often most efficient and most economical.

iGRAIN has developed monitoring expertise to monitor different biological eco-systems such as:

• Stored grain like wheat, rice, corn, etc.

• Special application for storage of barley for malting purposes

• Storage of cocoa or coffee beans

• Storage of nuts such as pistachio, cashews, almonds, hazelnuts, etc.

• Storage of feed pellets, including short-term storage before packaging.

• Monitoring of oil-seed meal from soybean, sunflower, cottonseed, etc.

• Storage of palm oil seed

• Monitoring of wood pellets or wood chips etc.

• Composting applications

All of these storage applications require monitoring and possibly aeration control. All sensors interfaces with the iGRAIN Dashboard Manager software for easy storage and inventory management.

Monitoring gases

The following gases can be monitored with iGRAIN sensors:

• Relative humidity in the storage container/silo

• Seed, grain, or other bio-material absolute humidity (EMC calculation)

• Carbon Dioxide – CO2 – monitoring infestation, and quantifying it

• Carbon Dioxide – CO2 – applied to monitor germination processes

• Volatile Organic Gases – VOC, monitoring organic volatile gases

• Hydrocarbon Gases – CₙHₘ, monitoring gases in the oil seed industry

• Oxygen monitoring – O2 – monitoring anaerobic conditions

• Temperature monitoring – always included

Catalogs

No catalogs are available for this product.

See all of IGrain‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Weather station

- Temperature weather station

- Temperature management system

- Real-time management system

- Relative humidity weather station

- Level sensor

- Building monitoring system

- Temperature humidity sensor

- Crop monitoring system

- Remote management system

- Grain sampler

- Smart management system

- Silo monitoring system

- Digital thermo hygrometer

- Grain monitoring system

- Moisture monitoring system

- Grain moisture sensor

- Digital temperature probe

- Pressure indicator

- Mobile management system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.