- Farm Management

- Measuring instrument

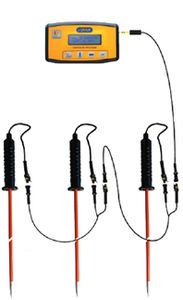

- Grain silo sensor cable

- www.i-grain.net

CO2 sensor cable for grain silotemperature

Add to favorites

Compare this product

Characteristics

- Application

- for grain silo

- Function

- temperature, CO2

Description

The iGRAIN Co2 Sniffer is an advanced CO₂ sensor system that detects stored grain spoilage at an early stage. The Co2 monitoring supplements temperature monitoring and will normally find a HOT-SPOT in the grain long before temperature monitoring. Its purpose is to support the detection of any unwanted biologic activity originating from insects, fungus, etc. in the stored grain.

Because the generation of CO₂ from the unwanted biologic activity is rather small, and because of the ambient level of CO₂ changes, sophisticated technology is required to detect the rise in CO₂ levels in the early stage.

iGRAIN has more than 10 years of experience with the CO2 monitoring and is indeed the company that made this technology available to the grain industry. The iGRAIN Co2 Sniffer was given an Innovation Award at the Victam Asia 2018.

Two standard Co2 Sniffer models are available:

.Extracts the air from inside the grain mass with a vacuum pump to analyze the extracted air in the CO₂ analyzer located in the cable head compartment, normally sitting on top of the silo.

.Measures the content of CO₂ with a micro CO2 analyzer in a specially designed compartment inside the grain mass.

Advantages:

.Earliest possible grain spoilage detection of insects and fungus.

.Reduce losses due to unwanted biologic activity

.Improve possibilities for grain management to take correct decisions earlier

.Operates with the iGRAIN Smart APP

Technical specifications:

Measures the CO2 concentration in the grain with advanced infrared analysis technology, with several advanced compensation systems to measure only the unwanted biologic activity from insects and fungus.

Catalogs

No catalogs are available for this product.

See all of www.i-grain.net‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Weather station

- Temperature weather station

- Temperature management system

- Relative humidity weather station

- Real-time management system

- Building monitoring system

- Level sensor

- Temperature thermo hygrometer

- Remote management system

- Crop monitoring system

- Grain sampler

- Smart management system

- Digital thermo hygrometer

- Grain moisture sensor

- Moisture monitoring system

- Silo monitoring system

- Mobile management system

- Digital temperature probe

- Grain monitoring system

- Automatic weather station

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.