- Farm Infrastructure

- Storage & Conveying

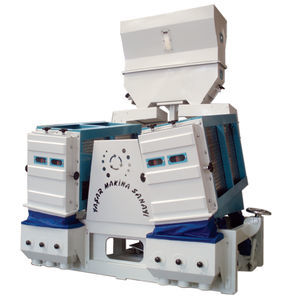

- Rice dehuller

- YASAR MAKINE METAL SANAYI VE TICARET ANONIM SIRKETI

Rice dehuller CSGA-5000automatic

Add to favorites

Compare this product

Characteristics

- Crop type

- rice

- Other characteristic

- automatic

Description

Peeler machines are used in paddy processing plants to peel the paddy from its shell and separating the peeled products into four groups. These products are; husks, dust, cargo rice and weak grains.

APPLICATION FIELDS

Yasar makine has developed a new paddy peeler for high capacity combined machine requiring rice processing plants.

The paddy peeler and the shell aspirator which are combined, provides more production capacity, less space, less energy

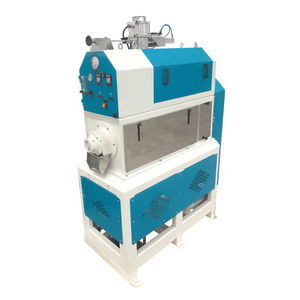

FEATURES & ADVANTAGES

• High quality and high performance

• Long life

• Minimum maintenance requirements

• Dust-free working opportunities

• Maximum security

• High production capacity

• Minimum breakage rate

• Low power consumption

• Combined peeler and peel separation system

• Compact size small installation space

• Touch control panel with easy to use PLC

TECHNICAL SPECIFICATIONS

-Two Ø255 x 350 mm roller peeler are used by the machine.

-There is a cooling fan system to improve the service life of the rubber rollers.

-The machine’s automatic product feeding system has an automatic level sensor.

-The rollers in the feed system use a vibrating feeder to ensure regular and equal feed.

-STo make the peeler rollers move in the opposite way a double sided belt is used.

-The machine’s aspiration section is of wide design to ensure the most efficient peeling possibility.

-There are inspection hatches on both sides of the aspirator for maintenance.

-Ease of use is provided with the PLC automated control panel.

-Stainless steel materials are used in products supply system.

-Merdanelerin mesafe ayarı otomatik kontrollü pnömatik sistemdir.

VIDEO

Catalogs

No catalogs are available for this product.

See all of YASAR MAKINE METAL SANAYI VE TICARET ANONIM SIRKETI‘s catalogsOther YASAR MAKINE METAL SANAYI VE TICARET ANONIM SIRKETI products

Rice Milling

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.