- Farm Infrastructure

- Storage & Conveying

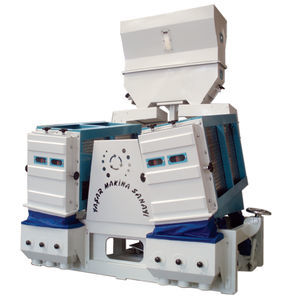

- Plansifter

- YASAR MAKINE METAL SANAYI VE TICARET ANONIM SIRKETI

Plansifter PPEM-5

Add to favorites

Compare this product

Description

Rice plansifter machines seperating breaking broken powder, zero broken, broken and rice.

General Features

The machine is constructed from rectangular and square profiles and is constructed in a solid structure combined with welding.

The connection of the machine hanging on the main frame is made with glass fiber sieve bar.

The product to be machined can be increased or decreased according to the flywheel balance, which provides the circular movement of the machine if necessary for the humidity difference.

The machine is bi-directional and has 6 layers of screen sieves and 5 pieces of chrome screen sieves with wooden frames in each direction.

Aspirator system is used to provide air circulation inside the machine.

The chrome sieve wires with wooden frame inside the machine can be changed quickly when requested.

Capacity: 4500 Kg / Hour.

Engine: 3 KW 1400 rpm Engine.

Features and Benefits

-Minimum volume

-Exceptional screening efficiency

-High performance

-High capacity

-Easy sieve changing

-Compact design

-Low maintenance need

-Possibility to adjust according to every product

-Low power consumption

-Silent operation feature

-Maximum security

Usage Area

Rice plansifter is generally used in paddy processing plants. Rice can be separated from each other by changing the number of the sieves with powder broken, zero broken, broken and rice.

VIDEO

Catalogs

No catalogs are available for this product.

See all of YASAR MAKINE METAL SANAYI VE TICARET ANONIM SIRKETI‘s catalogsOther YASAR MAKINE METAL SANAYI VE TICARET ANONIM SIRKETI products

Rice Milling

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.