- Farm Infrastructure

- Storage & Conveying

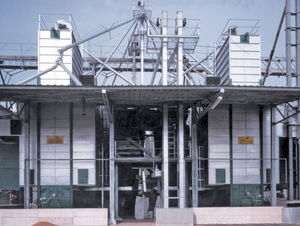

- Grain dryer

- ZANIN F.lli srl

Grain dryer MINIDRYstationarymobile

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Application

- grain

- Mobility

- stationary, mobile

- Capacity

Max.: 15 m³

(530 ft³)Min.: 1 m³

(35 ft³)

Description

COMPONENTI

Feed hopper

Feed-discharge auger

Motorised electric extractor

Centrifugal fan

Burner (gas methane-diesel)

Control panel

OPTIONAL

10 Km/h cart

Operating principle

The drying column is composed of air ducts buried in the grain.

The grain drops by way of gravity in a zig-zag pattern and is struck by a counter-current of warm air. The quantity of product discharged is regulated by a motorised electric extractor.

The product is collected in a hopper and sent down a vertical auger (optional bucket elevator), which repeatedly feeds the product into the drying column until the desired humidity level is reached (recirculating).

At the end of the drying process, the product is cooled and discharged by way of a bypass valve.

Catalogs

No catalogs are available for this product.

See all of ZANIN F.lli srl‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.