- Farm Infrastructure

- Storage & Conveying

- Grain dryer

- ZANIN F.lli srl

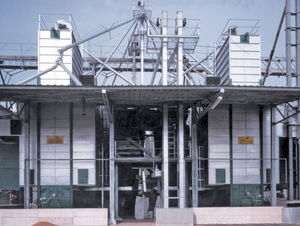

Grain dryer ERCL seriestower

Add to favorites

Compare this product

Characteristics

- Application

- grain

- Mobility

- tower

- Capacity

298 m³, 392 m³, 407 m³, 503 m³, 540 m³

(10,524 ft³, 13,843 ft³, 14,373 ft³, 17,763 ft³, 19,070 ft³)

Description

ENERGY-SAVING WITH INCORPORATED DRY SYSTEM

CARATTERISTICHE

Lower fuel consumption

Less electricity consumption

Less cracking

Higher protein value

Greater specific weight

Higher valid product rate

Excellent preservation in storage

COMPONENTI

Air duct

The panels forming the air chambers are made of: mineral wool sandwich panels, heated air section and saturated heated air section (prevents the formation of condensation and mulch inside the chamber).

Smooth interior and exterior walls.

Versions: Aluzinc-Galvanized-Precoated in various colours - Aluminium-Stainless steel 304. Reinforcing uprights and ledges with rung ladders are installed inside the dryer for control and maintenance purposes.

Fans

The depressurised drying system, offering maximum attention to detail, is the most suitable for dust containment. Each dryer is equipped with axial fans with variable pitch blades with different diameters, exploiting the machine's output and minimising consumption.

Zanin F.lli uses technologically advanced brands in the European fan sector to optimise the characteristics of its products.

Hot air generators

The following types of heating units are used for drying:

direct fired

indirect fired

diathermic oil or steam

Possible fuels are:

Methane gas

LGP

Diesel

Heavy oil, vegetable oil or sub-products

Biomass

The following types of burners are used:

pressurised

air

special for different types of fuels

Electrical cabinet

Dryers are equipped with electronic control devices and PLC management. Electronic control system to manage product moisture with contact sensor.

VIDEO

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.